Trina Solar 600W/550W PV modules took advantage of Trina Solar’s multi-busbars technology, low-voltage, high-current design, and advanced technology solutions such as non-destructive cutting and high-density cell interconnect technology. These technologies significantly improve the module’s performance in terms of anti-cracking and lower hot-spot temperature, further reducing the system cost. The optimized design of the Vertex module has become the new benchmark for high-power modules in large-scale power stations as well as distributed photovoltaic systems. The following is an analysis of the advantages and reliabilities of the Vertex series from five key perspectives: design, technology, testing, energy yield, and packaging.

1. Low-Voltage Design Feature Ensures the Excellent Resistance to Hot Spots

There are mainly two reasons that Trina Solar's 600W/550W series modules contribute to the outstanding resistance to hot-spot effect. Firstly, the 600W/550W series uses the most advanced cells production line, which holds the highest cells manufacturing standards in the industry. The leakage current Irev is minimized. Secondly, the Vertex 600W/550W series modules adopt a low voltage design. In 210 (55) module, 22 cells are connected to a bypass diode, compared to the 530W 182 (72) modules, the reverse bias voltage of the shaded cell is reduced by more than 8%. Also, there are 20 cells are connected to a bypass diode in 210(60) modules, which have the reverse bias voltage less than 23% of 590W 182(78) module.

Figure 1 shows the laboratory hot-spot test results based on the IEC hot spot test standard. The average hot-spot temperature of 210 55 pcs modules is 18 ℃ lower than 166 72pcs modules.

Figure 1 Hot-Spot Temperature Comparison of Different monofacial Modules with backsheet in Lab under IEC Standard

An outdoor hot-spot test carried out in early September, each module has a single cell-shaded 30% and under short circuit condition, different hot spot temperature of 166, 182 and 210 modules are recorded. The test result shows that the hot spot temperature of 166 and 182 modules is relatively equal, and the average hot spot temperature of the 210 modules is 19 ℃ lower than 166 and 182 modules.

The result further proved that the Vertex 600W/550W series modules have an excellent resistant ability to hot-spot effects on the market.

Figure 2 Outdoors Hot-spot Temperature Test results

Figure 3 Outdoor Hot-Spot Test of Different modules

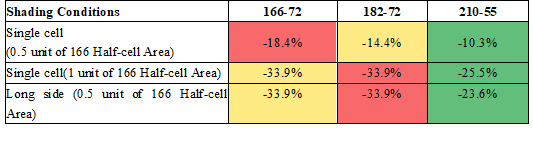

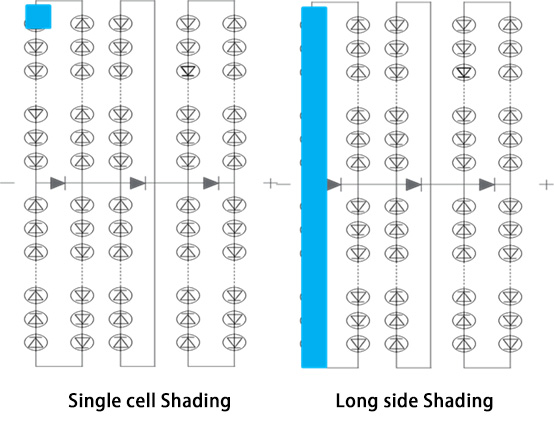

In addition, the power losses under different partial shading conditions are carried out, the shading area is use 166 half-cell as the baseline (137.08 cm2). By taking the Vertex 550W module as an example, due to the advantage of G12 large-size silicon wafers and innovative layout design in the PV module, the power loss under shading is smaller. When partial shading occurs, the Vertex 550W series modules demonstrated an outstanding power retention rate. A schematic diagram of the shading condition is shown in Figure 4.:

Table 1 The Power losses of the Modules Under Different Shading Condition (Based on two-diode Model)

Figure 4 Shading Conditions of Modules

2. Take the Initiative to Apply Non-Destructive Cutting Technology to Ensure the Optimal Mechanical Performance of Each Minimum Unit Cell in the Module and Eliminate the Risk of Cracking

Trina Solar's 600W/550W series modules took the initiative within the industry to apply non-destructive cutting technology. Its essence lies in the term "non-destructive", which is to say the solar cells are not damaged at all during the cutting process. After cutting, every minimum unit cell in the module is guaranteed to be in optimal performance. In traditional laser cutting, a laser is first used to melt the silicon wafer at a high temperature exceeding 1500°C, and then cut to a certain depth before breaking it. This will inevitably cause micro-cracks on the cutting surface and affect the mechanical strength of the cell. The non-destructive cutting adopts low-temperature laser technology, with the principle of thermal expansion and contraction to separate wafers by thermal stress. The section is to cut with a smooth surface without any micro-cracks. The mechanical strength of the cut cell will be close to that of the whole cell, which minimizes the risks of fragmentation and cracking during the process of utilization to a maximum extend. Provided with the same installation conditions, to compare the modules undergone cell encapsulation, on-destructively cutting process and the modules of conventional laser cutting process, the absolute value of power attenuation of the former can be reduced by 1%-1.5% under 5400Pa load conditions, therefore to provide the customer with a reliable value.

3. Current Adaptation Reliability Test to Ensure Safety

In line with the current output changes in the 600W/550W series modules, Trina Solar's R&D team has conducted a series of reliability tests, such as reverse current overload test, diode junction temperature test, junction box thermal runaway test, thermal cycling test, etc. When the bypass diode in the PV module is turned on outdoors, and the output current Isc=18.6A (the current of modules under usual operating condition generally does not exceed Imp≈17.5A under STC), the operating temperature of the diode is about 120 ℃. The current change will not increase the safety risk of the diode. Meanwhile, for the first time in the industry, the Vertex 550W/600W series modules have recently passed the reliability tests provided by third-party TüV Rhineland, which further demonstrates the excellent reliability and safety of Trina Vertex PV modules.

4. Excellent Low-Irradiation Performance Ensures Reliable Power Generation

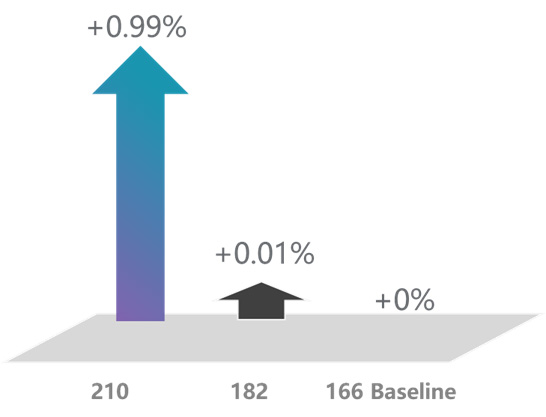

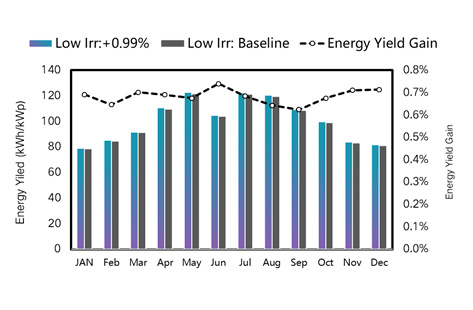

The Vertex 600W/550W series modules use a unique technology to ensure high power generation and optimize the fill factor of the modules to improve low-irradiation performance. Taking Changzhou as an example: PR200 W/m2 has been increased by 0.99%, and the energy yield gain increased by 0.68%.

Figure 5 Low Irradiation Performance Comparison among Various Products

Figure 6 Comparison of Monthly Energy yield gain in Changzhou under Low Irradiation

5. Short-Length and Two-Layer Vertically Stacking Packaging Method

By improving the vertical space utilization of the container, short-length and two-layer vertically stacking packaging method are used. The packing wattage of the standard container is further increased by about 9% compared to the first generation of Vertex, which provides our customers with a more economical, safe and reliable logistics solution.