What Are The Best Cell Chemistry & Cell Formats For Battery Cells?

- 23/06/30

- Reliability

As the global economy continues its mission to displace fossil fuel power for carbon free electrification, batteries are a vital storage tool to enable this energy transition, according to the World Economic Forum. Clearly, lithium batteries will be centre stage and seen as the technology of choice for the foreseeable future, but which features of this technology will prove the most attractive and capture market share?

The topic of which battery cell is "best" is a very broad subject, so we shall cover the entire subject over a few articles. In this article, we will focus on cell chemistry and cell format.

It is fair to say that lithium batteries had a pretty bad reputation in the early days, with numerous very high profile recalls and thermal events (or, in simpler terms, fires) in phones, laptops and electric vehicles.

The false perception that choosing a lithium battery automatically represents danger may still exist even today, but are they really? Let’s look at the facts.

Not all lithium batteries are the same

Lithium, Lithium-ion, Li-ion, and Li-Po are all generic terms for Lithium batteries. However, they are extremely different, with very different characteristics. For instance:

- LFP (Lithium Iron Phosphate) cells have a nominal voltage of 3.2 volts,

- NMC (Lithium Nickel Manganese Cobalt Oxide) cells have a nominal voltage of 3.6 volts, and

- LCO (Lithium Cobalt Oxide) cells have nominal voltage of 3.7 volts.

All of these have a similar make-up or chemistry, and all fit inside a cell enclosure of various shapes and sizes, also known as cell format.

Which cell chemistry is the best choice?

Chemistry choice may not seem like a big deal – after all, they all have graphite anodes, lithium-based cathodes and electrolyte. However, the differences are stark and have real world implications in terms of their voltage, lifetime, and safety.

Think of lithium batteries as an umbrella group with all chemistries with three pillars:

- In the first pillar, we have the full Oxide chemistries (e.g. LCO). Full Oxides have the highest energy density, fastest degradation rate and lowest safety.

- In the second pillar, we have mixed Oxide chemistries (e.g. NMC) with its high energy density and better degradation rate but still suffers from safety concerns especially under abuse.

- In the last pillar are the non-Oxide chemistries (e.g. LFP) which have a slightly lower energy content, but are very safe and stable even under abuse conditions and thus have a long lifecycle due to their excellent degradation characteristics.

As such, LFP is the clear choice for cell chemistry despite its lower energy density, simply because its low degradation rate results in higher value in the form of a much longer usable lifetime.

Which cell format is the best?

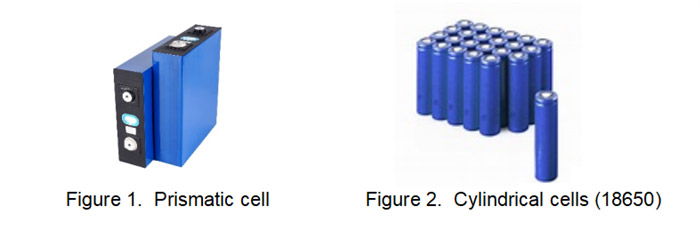

Battery cell formats can generally be divided into three main types.

- Cylindrical cells

- Prismatic cells

- Pouch cells

In simple terms, cell format is the outward appearance of the cell.

All three types of cell formats have merit for different areas, but for the purposes of this article, we will look specifically at Prismatic and Cylindrical cells only.

- Prismatic cells are encased in aluminium or steel for mechanical stability and are typically rectangular in shape. They are very space efficient (which ensures maximum energy density) but can cost a little more to manufacture than equivalent cylindrical cells. This is due to no industry standardisation for manufacturing or sizing being in existence. Modern prismatic cells are used in the electric powertrain and energy storage systems.

- Cylindrical cells are robust, and usually made from stainless steel, steel or aluminium. They have high energy density at the cell level, good mechanical stability and are the most commonly manufactured cell globally – this means lower production costs from standardised and automated manufacturing processes. In addition, cylindrical cells also have good cycle life with long calendar life. However, due to their shape, cylindrical cells lose their energy density advantage when they are assembled into larger packs.

In short, the high space efficiency and outstanding energy density of prismatic cells make them the superior choice in many types of applications.

Lithium batteries: New kids on the block? Not anymore.

Lithium-ion batteries first appeared commercially in the early 1990s with Sony’s handheld video recorder, which used LCO cells. Over the past three decades, cell chemistries and formats have evolved to value safety as well as energy density.

It is widely accepted that no single battery type or format is ultimately suitable for ALL applications. However, with all things considered, the emerging trend is that the combination of high capacity, LFP, and prismatic cells is ultimately the best option for utility-scale battery systems.

Superior performance with Trina Solar’s high capacity, LFP, prismatic cells

Trina Storage specialises in utility-scale battery storage systems. It offers the Elementa, a smart, large scale modular storage solution tailored for stand-alone and co-located renewable energy sites.

Each Trina Storage Elementa cabinet is equipped with ~2.2 MWh of energy utilising state-of-the-art, high capacity, LFP, prismatic cells to deliver the best option for utility customers.

The Elementa system is also fully integrated onsite with a dedicated Battery Management System, Energy Management System, Power Conversion System, medium-voltage equipment and transformer, ensuring full optimization for lower OPEX through flexibility, smooth installation, and efficient maintenance.

Want to learn more about our innovative energy storage solutions and other industry insights? Join our newsletter to get the latest and greatest straight into your inbox, or contact us if you have any questions.

Relevant Topics

Smart Energy Solutions

delivered straight to your inbox